|

| Replacement Battery Separator |

December 2019:

I installed a replacement battery separator and it works differently from the old one.

See Note 5 in the Battery Separator section, below.

September 26, 2019:

After I installed the digital voltmeter I was able to more closely monitor the coach battery voltage as well as the operation of the separator. Earlier this year I purchased a replacement separator as a "spare". The old separator seems to work inconsistently or intermittently. For example with the engine running and a 14V chassis battery voltage the separator will connect the chassis and coach batteries.

But sometimes it does not! Go figure. I've decided to install the spare and I'll provide an update after I do.

October 6: I added information on

"clicking" battery separators. This has been reported by owners.

To go to the section on the battery separator, click here:

Click here to go to the post section about the battery separator.

June 26, 2019 added the SOC table for the AGM batteries in my 210P. Note, I replaced those batteries and the table for your batteries may differ.

July 3, 2019 clarified separator main and aux connections.

================================================

Read the notes at the end before proceeding! This post is not a recommendation that owners perform their own electrical service. Working with electricity can be dangerous and can result in personal injury, or death or damage to your Roadtrek.

Sorry if I created a scare, but one does have to be careful if tinkering with electrical systems. Mistakes can be very costly, or can result in personal injury.

My 2013 Roadtrek 210P has:

- 2 x 6 volt AGM coach batteries, about 220Ah

- Tripplite 750W Charger/inverter

- Battery Separator (bidirectional)

- LED 12V display (four round indicators)

- Digital 12V display (added by me)

- Onan generator (2800 watt)

- 50 watt solar panel, for charging the coach batteries (added by me)

2013 Roadtrek 210P display/switch panel

This is the display/switch panel on my 210P. In the photo the Onan generator is running and supplying 120VAC power. The Battery Disconnect is

ON and this is indicated by the

Battery On blue indicator. As a consequence the batteries are charging:

Charging the coach batteries

It is possible to charge the coach batteries:

- While on 120V "shore power" and using the Tripplite

- While running the vehicle engine (see the Battery Separator section for limitations)

- By running the Onan generator and using the Tripplite.

- On solar

The limitations of the battery LED indicator

The LED indicator of the Roadtrek is a voltmeter which is somewhat limited. It indicates these battery conditions while the soft

BATT button is pressed:

- L - Low

- F- Fair

- G- Good

- C- Charging

Note that the "C" indicator may be on even when the battery is discharging. This may occur shortly after disconnecting the coach from AC or stopping the vehicle engine. The reason is because the coach battery voltage is higher than normal 100% charge. This is what is called a battery "surface charge" and after a few minutes with a small DC load such as the slowly running roof fan, this charge will be dissipated and the true condition of the battery will be indicated.

In the photo the Battery Disconnect switch BATT is

ON as indicated by the illuminated "

Battery ON" light. Pressing the Battery button displays the battery situation. The highest (rightmost) illuminated indicator displays the condition, which in the photo is a

C for

Charging:

Using a Voltmeter to Monitor the Battery Voltage

Monitoring the coach battery voltage is helpful for determining battery capacity. We may want to know how much energy is available in our coach batteries. A voltmeter is useful for doing this.

My Roadtrek didn't have a voltmeter, and the power/switch/display area isn't set up for one. However, there is a 12V "cigarette lighter" style receptacle in the rear overhead compartment, above the DVD player. Unplugging my powered antenna allows me to plug in a voltmeter to check the battery voltage:

|

| 12V receptacle |

Here's a typical digital plug-in voltmeter. These can be purchased for as little as $7:

|

| Plug-in Digital Voltmeter |

What does that voltmeter display mean?

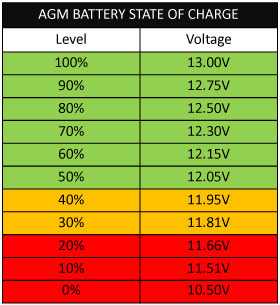

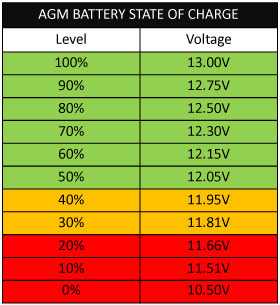

Here's a typical chart for AGM batteries. If we are aware of the voltage at the batteries, we have a rough idea of the "capacity" remaining. For example, if your voltmeter displays 12.50 volts, then you have used about 20% of the capacity or available energy in your batteries. However, I must note that it is not recommended to fully discharge batteries to 0%. That will ruin them.

You will have to decide how low you want to run your batteries. For longest life under moderate temperatures (77F is ideal) some recommend not dropping below 50%, or about 12.05V. Dropping to 20% (80% discharge) reduces battery life, but provides energy for a longer time. That's discharging to about 11.66V. Going lower will severely reduce battery life. Fully discharging AGM batteries can damage and ruin them. What does repeatedly discharge below 20% mean? It means severely reducing battery capacity, to the point the batteries cannot provide energy when disconnected from the Tripplite charger (when charging the battery).

Note that you might have poor batteries and be unaware. The 750W Tripplite inverter/charger can provide up to 45A (amperes) of charging current when on shore power. That's about 540 Watts. The Tripplite can not only charge batteries, but also power 12V DC appliances including lights, fan, propane furnace and so on when the Roadtrek is connected to shore power, even with poor batteries.

Having a voltmeter helps to determine just how long your batteries can support your RV when you are disconnected from AC power. For example, suppose you are running your fan, there are interior lights on, the occasional water pump, and your 3-way refrigerator is on propane (some 12V is used). After three hours the voltmeter indicates 12.5V. That means it took 3 hours to use about 20% of your battery capacity. Another 3 hours will use an additional 20% or more. That implies you'll have enough battery power to make it through the night (lights off, pump off and fan on).

This table is

typical. Your AGM batteries may vary somewhat.

|

| Typical AGM Battery Table |

I replaced my AGM batteries and this is the SOC table provided by the manufacturer. Your batteries may differ:

What does "reducing battery life" really mean?

AGM and gel lead-acid batteries are chemical devices. They generate electricity using lead plates or mats and an acid liquid. As we repeatedly discharge these batteries, certain deposits form inside them that reduces the capacity. Capacity is the ability to deliver full current for a certain amount of time before the voltage decreases below a useable level. As batteries age, that ability diminishes. For example, a new, fully charged battery can provide a specific amount of current for a specific length of time. Think of this as ability to run your fan, lights, DC for a propane refrigerator and a laptop. With new batteries, you might be able to do that all night. As the batteries age, the length of time decreases and you will find the batteries can no longer do so. And the lights will go out before dawn, whereas before they could be left on all night.

Alternative Voltmeter

I decided to add a digital voltmeter/ammeter. The advantage is I can monitor the amount of current being used and the digital meter provides me with a better idea of the "state of charge" and how much electrical energy might be available. The higher the current, the faster I will drain the batteries. The meter includes a Watt hour counter ("energy"), so I can roughly monitor how much energy is used overnight, should I choose to do so. The meter includes both high and low voltage alarms. This is detailed in another post:

The following data is according to the Tripplite 932768 manual for 750 Watt "PowerVerter DC-to-AC Inverter/Chargers", the Tripplite data sheet and a Roadtrek Manual

Charging the AGM batteries

The batteries can be charged from 120VAC. This is either via shore power or by running my Onan generator. One thing to keep in mind is to turn

ON the battery disconnect switch

before plugging the RV into AC power or starting the Onan generator. That is per Roadtrek recommendations for my RV.

How long can it take? If the batteries are depleted, it can take 12 hours

or longer to fully charge the batteries.

Are there circumstances under which I can't charge the batteries? If the battery voltage decreases to below 10.0V (+/- 3%, or somewhere between 9.7 and 10.3 volts) a low voltage cutoff will occur. The Tripplite inverter/charger will

not charge the batteries if the battery terminal voltages fall that low. If your vehicle engine is running, the battery may be charged via the standard alternator,

if the battery separator allows (see the Battery Separator comments below). A underhood battery separator isolates the chassis battery from the coach batteries when the engine is not running. However, batteries below 10.5 volts should be checked. They could be damaged.

How can I determine the state of charge? The Tripplite charger/inverter includes a display. However, it cannot be viewed without removing a cover. Here is a photo with the cover removed. The Tripplite has two rows of LED indicators. One blinks green when on 120VAC and the Inverter switch is "OFF". Otherwise if on 120VAC and the Inverter switch is "ON" then it will be steady green. The switch is located on the Roadtrek display/switch panel near the side entry door. (see the first photo in this post, above).

The other Tripplite indicator goes from off to red to yellow to green depending upon the state of charge of the coach batteries. If charged more than 91% and on AC, one will be blinking green (on AC and inverter off) and the other will be steady green (91% or better charge).

The Tripplite is located in an interior compartment to the left and in front of the powered sofa when you are facing the rear of the RT. The Trippite has a fan and at times you will hear it running.

However, there are exposed connectors/wiring so you do need to be careful. If you have any concerns, get a pro to do this. DO NOT TOUCH ANYTHING. After you have a pro demonstrate this to you, you can decide if you want to do it yourself in the future.

To reveal the Tripplite, lift up on the top wooden cover at the front and then slide it forward.

|

| Tripplite and DC Electrical Compartment |

The next photo is a close-up of the indicators on the Tripplite. The arrow points to a flashing green LED. That means the Tripplite is on AC with inverter OFF. The other indicator which is below the blue cable is the charging indicator. In the photo the bottom LED is green which according to the Tripplite manual indicates "battery capacity charging/discharging 91% - Full"

Here's the table from the Tripplite manual. There are a number of switches for configuring the Tripplite. These LEDs function with Switch in "AUTO/REMOTE" or “Charge Only” Position. That is how my Roadtrek was delivered.

Approximate Battery Charge Level while charging and discharging (bottom indicator in the photo below):

- Green = 91% to Full Capacity (see the Tip below)

- Green and Yellow = 81%-90%

- Yellow = 61%-80%

- Yellow and Red = 41%-60%

- Red = 21% to 40%

- All three LEDs off = 1% to 20%

- Flashing Red = 0% (Inverter shutdown)

Tip: How can we determine the Battery Charge Level above 91%? At about 91% the AC power of the Tripplite is about 10 amperes. At about 100% charge it will decrease to 2 to 4 amperes, assuming the inverter function is OFF. Monitoring the AC current consumption of the Tripplite can aid us in determining the battery charge level above 91%. I have a Progressive Industries EMS on my 210P and I can monitor the AC current consumption. If you have a similar arrangement, so can you. However, you do have to avoid running anything else in the coach to get a reliable reading from the AC draw of the coach.

Tripplite Fault Conditions (bottom indicator in the photo below):

- All three flashing slowly (1/2 second on, 1/2 second off) = Excessive discharge (inverter shutdown)

- All three flashing quickly (1/4 second on, 1/4 second off) = Overcharge (Charger shutdown)

The arrow in the photo points to the 120v power "Line green LED":

- Steady Green = Roadtrek inverter switch "ON" and the coach is on AC power (shore power or Onan generator)

- Flashing Green = Roadtrek inverter switch "OFF"

- Yellow = Roadtrek inverter switch "ON" and Coach battery providing power to 120V receptacles via the inverter.

- Red = Roadtrek inverter switch "ON" and power demanded of the inverter exceeds 100% load capacity

|

| Tripplite LED Indicators |

Tripplite Operation and Inverter Selector

The Tripplite has a 3-way slide switch for selecting the "Operating Mode". See the photo below:

Left Position -

Auto/Remote

Center Position -

DC OFF

Right Position -

Charge Only

The "

Auto Remote" position ensures that the connected equipment receives constant, uninterrupted AC power. It also permits the Inverter/Charger to be remotely monitored and controlled (in my 210P the Roadtrek inverter switch turns on and off the "inverter" operation if the Tripp-Lite slide switch is in this position).

The "

DC OFF" position de-energizes the unit and connects AC OUT to AC IN. In my 210P this slide switch position disables the Roadtrek inverter selector.

The "

CHARGE ONLY" setting allows the Tripplite to charge the batteries faster by turning off the inverter, which halts battery discharging.

|

| Operation Switch in DC OFF position |

Battery Separator.

Battery Separator - Bidirectional

The battery separator is under the vehicle hood. It controls the connection of the vehicle battery and the coach batteries. In my 210P the battery separator is a "

bidirectional" 200A module with a relay for 12V systems. You may have a "

unidirectional" model and if so, your battery separator operates differently than the following; for a unidirectional separator see the description in the next section.

The [bidirectional] separator monitors the engine ("Main") and coach ("Aux") batteries. The manual states "If

either battery bank is above the connect threshold [13.2V], the relay [closes and] connects the two banks together. If

either battery is below the disconnect threshold [12.8V] the unit will open the relay." However, once connected both batteries are at the same voltage. Opening the relay disconnects the engine and coach batteries, preventing the draining of both. "The connect threshold is set to a nominal voltage of 13.2V, which would only be reached when the charging system is operating. The disconnect voltage is set to a nominal 12.8V, which is near the full charge resting voltage of the batteries. "

I've monitored the separator and it seems to be intermittent. At times, if the coach battery voltage is less than 12.8V the engine battery

will not charge the coach batteries because the separator disconnects if either battery bank is below that voltage. When this occurs, the battery must be charged via 120VAC (shore power or Onan generator). Or via solar. In other words, the battery separator in my Roadtrek doesn't seem to consistently connect my vehicle alternator to the coach battery if the engine battery is 14V and the coach battery is less than 12.8V. That's a coach battery that is 90% charged. See note 7.

According to the separator manufacturer: The connect threshold is set to a nominal voltage of 13.2V, which would only be reached when the charging system is operating. This will cause the relay to close and the charging system can charge both banks of batteries. The disconnect voltage is set to a nominal 12.8V, which is near the full charge resting voltage of the batteries. This will cause the relay to be opened shortly after the engine is stopped, attempting to preserve 100% of the starting battery capacity for engine cranking."

Note 1: In my Roadtrek the terminal labelled "

Aux" is connected to the

coach batteries. The terminal labelled "

Main" is connected to the

chassis battery:

Note 2: The vehicle alternator (Main) will connect to the coach batteries (Aux) if either the vehicle or coach batteries are above the "connect" threshold of about 13.2V, which is 100% charge. After connecting the batteries will remain connected unless one of the batteries falls below 12.8V. This was confirmed with a new battery separator. See Note 5.

Note 3 : The separator includes a momentary "auxiliary start function". The start terminal must see at least 3V* to activate. The auxiliary [

coach] battery must read at least 10V*." "This is the input for engine start signal override. When power is applied to this input, the relay will close if the Aux. Battery [

coach] is no less than 0.85 Volts below the Main battery [

chassis]." In my Roadtrek this is not used.

Note 4: According to the separator manufacturer, "* = Typical voltage settings have a +/- 2% tolerance".

Note 5: Update December 2019. I replaced the battery separator and the operation of the new one is different than the old one. If either the coach or engine battery is above the "connect" voltage threshold of about 13.2 volts then the separator connects both coach and engine batteries. I've monitored this for several weeks and the operation is consistent. If the engine is running the engine battery voltage is about 14.0 volts and the separator connects the engine battery to the chassis battery. If the engine is not running and I connect the Roadtrek to shore power, the Tripplite charge voltage rises to above 13.4 V and the chassis batteries and Tripplite are connected to the engine battery. This is not the way the old separator operated and I can only assume that the old separator had a flaw or failure.

Separator Options

The separator includes some options, including a "start signal" but that is

not wired on my Roadtrek. The "start signal input" is the input for engine start signal override. When power is applied to this input, the relay will close if the Aux. [

coach] Battery is no less than 0.85 Volts below the Main [

chassis] battery.

Where is the Separator located?

The battery separator is the device in the center of this photo with the two red rubber boots. In my Roadtrek the terminal on the right is labelled "

Aux" and is connected to the

coach batteries. The terminal on the left is labelled "

Main" and is connected to the

chassis battery:

Alternate Battery Separator - "Unidirectional" Type

The battery separator is under the vehicle hood, see the photo above. It controls the connection between the vehicle battery and the coach batteries. In my 210P the battery separator is a "

bidirectional" 200A module with a relay for 12V systems. The following is the description of a "

unidirectional" model. These two models operate differently. You need to determine which you have in your RV.

The

unidirectional separator is a 200A battery separator modules with an integrated relay for 12V systems. The separator monitors the engine and coach batteries. If the Main battery is above the connect threshold, the relay connects the two battery banks together. If the Main battery is below the disconnect threshold the separator will open the relay. You will have to determine which battery bank, Chassis or Coach is connected to the "

Main" terminal.

The connect threshold is set to a nominal voltage of 13.2V, which would only be reached when the vehicle charging system is operating. This will cause the relay to close and the engine charging system can charge both the engine and coach batteries. The disconnect voltage is set to a nominal 12.8V, which is near the full charge resting voltage of the batteries. This will cause the relay to be opened shortly after the engine is stopped, attempting to preserve 100% of the starting battery capacity for engine cranking.

Battery Separator - Bidirectional - "Clicking"

The battery separator is under the vehicle hood, see the photo above. From time to time, you might hear a "clicking" sound if your hood is open. That could be the relay of the separator opening or closing.

For a bidirectional separator the relay will close as noted above if the vehicle battery/alternator is above 13.2V and the coach batteries are above 12.8V. Or vice-versa. If either of these falls below 12.8V the relay will open. When the relay closes it connects the vehicle battery/alternator to the coach batteries and when it opens it disconnects or separates these batteries.

The bidirectional will connect the vehicle and coach battery systems if the coach rises about 13.2V and the vehicle is above 12.8V.

At rest, my vehicle battery is about 12.6V. Fully charged my coach batteries are about 13.2 volts after dissipating the "surface charge".

If one has a solar charging system for the coach batteries, it would be possible for intermittent connection of the two systems if the solar system rises above 13.2V and the engine battery is above 12.8V. Depending upon load and sunlight conditions, if the coach battery falls below 12.8V or about 90%, then the separator relay will open, disconnecting the vehicle and coach batteries. If the sun comes out, or solar improves and the coach battery terminal voltage increases to above 13.2V (which will happen while charging) then the separator relay will close, connecting the two battery systems. As the coach battery discharges, the terminal voltage will decrease. When sunlight increases, then the separator will again close the relay, "click" and the two battery systems will be connected.

Of course, a faulty separator may also close the relay at unexpected moments.

Solar.

Solar:

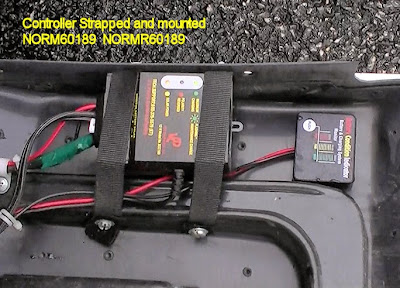

In 2014 I added a 50-watt solar panel and a desulfating solar controller. Using a 50-watt solar panel provides a maximum 4.17 amperes of charging current at 12V during peak sunlight conditions. That's more than sufficient for maintaining or topping off the batteries.

Notes:

- This post is not a recommendation that owners perform their own electrical service. Working with electricity can be dangerous and can result in personal injury, or death or damage to your Roadtrek.

- This information is provided "As Is" and no warranty or claim of accuracy is given. Your Roadtrek and its equipment may be very different than what is portrayed here.

- Refer to the Roadtrek owners manual and the Tripplite Owner's Manual for complete information.

- The Tripplite inverter/charge includes 120V surge protection. In other words, outlets that are powered by the "invert" mode will have surge protection. Any others in the coach will not have any surge protection unless it is added. In my case, I have an electrical management system (EMS) on the shore power line. I don't have such a thing on the generator power output.

- For troubleshooting of the Tripplite, refer to the owners manual.

- This post is based on several other posts in this blog as well as recent social media posts by me. I'm providing this so I won't have to write this up again.

- My coach batteries exhibited difficulty at about 3 years. I suspect the problem was the model battery separator Roadtrek installed in my 210P. The separator won't connect the vehicle alternator to the coach batteries unless the coach batteries are at 100% charge.

- All info on the battery separator is per the manufacturer's data sheet.